News from the 71A Locomotive Group

June 2025 News UpdateRailtour duties for 33012On Thursday 26th June, 33012 worked the 0Z33 09:20 Swanage to West Ruislip LUL Depot. On Friday 27th June, 33012 worked UK Railtours 'Another Really Good Positioning Move', hauling the London Transport 4TC set from Princes Risborough to Tonbridge.

The 'Another Really Good Positioning Move' is seen here at New Barn bridge, just past Gomshall ascending the 1 in 96 gradient between Guildford and Redhill. Friday 27th June 2025. Photo courtesy of Julian Clark. On Saturday 28th June, 33012 (with GBRf 66754) hauled the UK Railtours 'The Baker's Dozen - Rebaked' tour, again with the 4TC set, from Tonbridge to Tonbridge via 13 London termini. On Sunday 29th June worked (with GBRf's 73202 and 73212) UK Railtours 'Curvy Weaver', from Tonbridge to Tonbridge via various rare lines in the Wembley area. On Monday 30th June 33012 travelled back to Swanage light engine.

Solo in the Surrey Hills, in over 30 degrees of heat, D6515/33012 climbs the 1 in 96 past Westcott Ranges crossing, between Dorking and Gomshall, on its return from Tonbridge to Swanage on Monday 30th June. Photo courtesy of Julian Clark. February 2025 News Update2025 71A AGMThe 2025 AGM is to be held on Sunday 6th April 2025 at 13.30 hours in a meeting room inside Eastleigh Railway Works. Anyone attending the AGM needs to be at Railway Works Gate 2A by 13.00 promptly, so that they can be escorted (please ring the Group Secretary, Tim James on 07925 691260 if you running a few minutes late). April 2024 News UpdateUpcoming Galas And RailtoursThe following dates are for forthcoming railway galas and railtours, that are currently planned to involve 33012 for all or part of the event:

Friday 3rd May 2024 – "Return of the Shedi" railtour from

Eastleigh to Cardiff Central (and return)

Saturday 4th May 2024 – "May the Fourth be with You" railtour from

Eastleigh to Portsmouth Harbour (Rev), Bristol TM, Exeter St Davids,

Salisbury, Waterloo, and back to Eastleigh via Chertsey and Havant

Thursday 9th May 2024 – "Jurassic Crompton" railtour from

Eastleigh to Swanage (one way)

Friday 10th May through to Sunday 12th May 2024 – Swanage Railway Diesel Gala

Sunday 12th May 2024 – "Return of the Jurassic Crompton" railtour from

Swanage to Eastleigh (one way)

Thursday 6th June 2024 – "Holt Hoover" railtour from

Eastleigh to Sheringham (one way)

Friday 7th June through to Sunday 9th June 2024 –

North Norfolk Railway Rails and Ales Gala

Sunday 9th June 2024 – "Cromer Crompton" railtour from

Sheringham to Water Orton (one way)

Saturday 27th July 2024 – "Dean Forest" railtour from

Basingstoke to Lydney (and return)

Sunday 28th July 2024 – "Waterside Wanderer" railtour from

Fenchurch St to Anglia Branches (and return)

Please note, that these events and railtours are the ones that have now been confirmed and advertised by the relevant organisers. Please always check with the relevant organiser in case of any last minute changes, before booking any trains to or form, or accommodation nearby, for any of these events or railtours. February 2024 News Update2024 71A AGMThe 2024 AGM is to be held on Sunday 7th April 2024 at 13.30 hours in a meeting room inside Eastleigh Railway Works. Anyone attending the AGM needs to be at Railway Works Gate 2A by 13.00 promptly, so that they can be escorted (please ring the Group Secretary, Tim James on 07925 691260 if you running a few minutes late). January 2024 News UpdateSwanage Railway's Winter Warmer GalaHeld on Saturday 6th and Sunday 7th January 2024, 33012 and 33111 both featured in this event.

During the Swanage Railway's recent Winter Warmer Gala, 33012 is seen at Swanage on Saturday 6th January 2024, having just arrived with the 15.00 Norden to Swanage passenger service. Photo courtesy of Graham Miles.

33012 is seen approaching Corfe Castle with the 13.02 Norden to Swanage demonstration freight service, while 33111 is waiting with the 12.45 Swanage to Norden passenger service on Saturday 6th January 2024. Photo courtesy of Graham Miles.

Later on the same day the roles are now reversed, with 33111 seen approaching Corfe Castle with the 16.02 Norden to Harmans Cross demonstration freight service, while this time 33012 is waiting with the 15.45 Swanage to Norden passenger service on Saturday 6th January 2024. Photo courtesy of Graham Miles.

33012 is seen at Harmans Cross with the 15.45 Swanage to Norden passenger service on Saturday 6th January 2024, waiting for a steam hauled passenger service coming the other way to pass. Photo courtesy of Graham Miles. June 2023 News UpdateHandover of the "Axton Angel" Headboard to Dave Axton's FamilyBack in July 2015, the 71A Locomotive Group's former Technical Officer Dave Axton sadly passed away far too soon after a battle with leukaemia. Dave had been the Group's Technical Officer from the start of the Group in 1996 through to 2011, when he handed over to our current Technical Officer, James Cox. After Dave's passing, 71A Locomotive Group working volunteer Kevin "Hartley" Hare decided to honour Dave's contribution to the Group, by making the "Axton Angle" headboard as seen in the photos below. After recently seeing a past photo of 33012 with the headboard on the front, Dave's widow Elaine had been in touch with both the Swanage Railway and the 71A Locomotive Group, to enquiry what had become of the headboard. This resulted in Elaine and a few members of her family being invited to the Swanage Railway on Friday 12th May (during the recent Diesel Gala), to be presented with the headboard. Elaine and her son Kevin travelled in the cab of 33012 from Corfe Castle to Swanage on the 10.32 River Frome to Swanage, with 33012 wearing the headboard once again. This gave Elaine and her son a chance to savour the locomotive that Dave had been instrumental in saving. At Swanage, Elaine was formally presented with the headboard by Kevin Hare, before Elaine and the family travelling back to Corfe Castle on the 12.39 Swanage to River Frome hauled by 50026 and 50021. Alas they had to be back at Corfe Castle by a certain time, hence why they weren't able to sample 33012 on her next working north. The highlight for everyone though was the smile on Elaine's face, when holding and looking at her Dave's headboard.

Elaine Axton (centre) is seen holding the "Axton Angel" headboard, with her son Kevin Axton (left) and 71A Locomotive Group working volunteer Kevin "Hartley" Hare (right - who originally made the headboard) at Corfe Castle on Friday 12th May 2023, before their trip on 33012. Photo courtesy of Sandy Lewis.

A close-up of the "Axton Angel" headboard, which was made by 71A Locomotive Group working volunteer Kevin "Hartley" Hare to honour Dave Axton, after his untimely death in July 2015. Photo courtesy of Alan R. Hawkins. May 2023 News Update2023 Swanage Railway Diesel GalaThe 2023 Diesel Gala featured both 33012 and 33111, here are a few photos from that event.

We could be accused of being biased, but I think you'll all agree that 33012 really was the crowning glory of this year's Swanage Railway Diesel Gala!!! In the photo above, 33012 is seen at Swanage on Saturday 13th May 2023, having just been uncoupled from the stock of the 18.15 Norden to Swanage. The giant crown in the foreground was part of the Swanage station decorations for the previous weeken's celebration of the King's Coronation on Saturday 6th May 2023. Photo courtesy of Alan R. Hawkins.

33111 is seen crossing Corfe Common with the 12.15 Swanage to Corfe Castle on Sunday 14th May 2023. Photo courtesy of Graham Miles.

33012 is seen approaching Corfe Castle with the 11.32 River Frome to Swanage on Sunday 14th May 2023. Photo courtesy of Chris Bracey.

Same loco, same train, different location. 33012 is now seen leaving Corfe Castle with the 11.32 River Frome to Swanage on Sunday 14th May 2023. Photo courtesy of Graham Miles. Friday 3rd June 2022Final stage of Cab Overhaul:Welcome to this special news update covering the final stage of the cab overhaul on 33012 (D6515). With the cab overhaul on 33012 now completed, it is only right that the 71A Locomotive Group highlights the magnificent support that the Group has received from Barry Stephens, the boss of Arlington Fleet Group Ltd, and all of his staff. Barry has been very generous in providing the Group the workshop space that allowed us to carry out the work on 33012 undercover and in the dry, something that is critical when we were removing the roofs off both of 33012's cabs. On top of this, we had access to overhead cranes, welding equipment, and other engineering equipment. This support that the Group received from Barry and all of his staff is gratefully appreciated by the committee of the 71A Locomotive Group. February 2023 News Update2023 71A AGMThe 2023 AGM is to be held on Sunday 2nd April 2023 at 13.30 hours in a meeting room inside Eastleigh Railway Works. Anyone attending the AGM needs to be at Railway Works Gate 2A by 13.00 promptly, so that they can be escorted (please ring the Group Secretary, Tim James on 07925 691260 if you running a few minutes late). October 2022 News UpdateWork Carried Out on 33012 during the Recent B4 ExamThe following series of photos were taken during the recent B4 examination of 33012 that was carried out from Friday 14th through to Sunday 16th December 2022. Unfortunately not all the work carried out during that long weekend was photographed, but the following photos will give you a good idea of the work that is needed to keep 33012 operational. This work was carried out by James Cox (the 71A Locomotive Group's Lead Technical Officer and all round Class 33 technical guru), Kevin Hare, Joe Loughlin and Alan Hawkins (all three being 71A Locomotive Group Working Volunteers on 33012). Air Brake System Feed Cut-0ff ValvesAs you'd expect, ensuring that the brake systems on 33012 are in tip top condition is of prime importance, so maintenance of the moving parts within the brake systems is one area that needs to be done regularly. One part that needs regular attention are the feed cut-off valves within the air brake system. These need dismantling, cleaning, checking for any damage from water condensation in the air, and then re-greasing and re-assembly. There are two of these feed cut-off valves under each of the desks in both cabs, one from each pair is part of the Driver's Safety Device system (the DSD), and the other one from each pair is part of Automatic Warning System (the AWS). All the following photos are copyright Alan R. Hawkins.

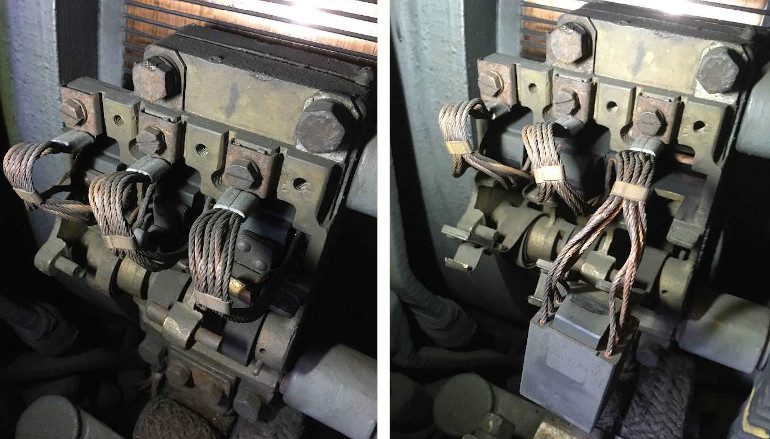

The photo above shows one of the Feed Cut-Off Valves dismantled prior to re-assembly. Electrical GeneratorsAnother area on 33012 that needs regular maintenance to ensure it remains in tip top condition, are the three electrical generators that are bolted to one end of 33012's Sulzer engine. The first of these which is bolted right up against the Sulzer engine is the Heater Generator, which provides the ETH or electrical train heating to any carriages being haulled by 33012. The next is the biggest one which is the Main Generator, which provides the electrical power to 33012's traction motors to propel 33012 along. The third and final one is the Auxiliary Generator, which provides all the internal electrical power to 33012 itself. Keeping these electrical generators clean and tidy is paramount, as is checking that the carbon brushes are in good condition, replacing them if they are badly worn.

The photo on the left shows the Heater Generator (with one of its inspection covers removed), and the photo on the right shows the larger Main Generator and the smaller Auxiliary Generator.

The photo on the left shows the carbon brushes in one of the brush boxes in the Main Generator in their normal position, while the photo on the right shows one of the carbon brushes removed for inspection. Fuel Filters - ReplacementOne job that is common to any type of vehicle with a diesel or petrol engine, regardless of whether they are trains, cars, ships, planes, generators, etc, is the regular replacement of the fuel filters.

The three photos above show the replacement of the double stacked fuel filter elements on 33012. Dry Filters - Replacement or CleaningAnother job that is common to other types of vehicle, is the replacement or cleaning of the dry filters. The two photos below show two of the dry filters on 33012 after replacement or cleaning.

The photo on the left shows one of the engine air filters after just being changed with a new filter element. There are four of these filter elements in total. The outer faces start out as pink, but by the time they are due to be changed, they will be dark grey or black !!! The photo on the right shows the vacuum exhauster line filter, which needs blowing out with a high pressure airline, to remove all the dust and small particles from the reusable filter element. This reusable filter element is about the size of a large paint pot. June 2022 News UpdateKeighley and Worth Valley Railway Diesel Gala Report - James Cox:Not long after returning to the Swanage Railway (from SVR Diesel Gal), 33012 was on her travels again a few weeks later, with a visit to the Keighley and Worth Valley Railway (KWVR) Diesel Gala in early June 2022. The mainline transit moves for the KWVR Diesel Gala would have made admirable railtours if that had been possible !!! Northbound Mainline Move - Day No 1 - Monday 6th June 202233012 hauled 50026 from Swanage to Kimberley (on the Mid Norfolk Railway) to collect 33202, running as 0Z33 Swanage to the Mid Norfolk Railway (MNR). Departing Wareham at 18.17, we were routed via Southampton Central, Winchester, Woking, Chertsey, Kew East Jct, South Acton (for a crew change), Willesden Jct, the North London Line, Alexandra Palace, Herford Loop, Cambridge, Ely, and Wymondham (arriving very early in the morning at 01.34 !!!). The trip to Wymondham went by without any problems, and on arrival at Wymondham, the WCR crew propelled 50026 onto the Mid Norfolk Railway where a MNR crew of Stewart Robinson (owner of 33202), and James and Stephanie Garthwaite were waiting with 33202, which was coupled to the country (Dereham) end of 50026 and then hauled 50026 and 33012 to Kimberley Yard on MNR. At Kimberley Yard, all three locos were secured, and James Garthwaite gave the two WCR drivers a lift to their hotel near Norwich, while Stewart Robinson had booked a cottage more local to Kimberley for me to stay in. Northbound Mainline Move - Day No 2 - Tuesday 7th June 2022The same WCR drivers who had worked the train to Wymondham, also worked the train from Wymondham to Doncaster. Therefore, the timings were set to give 12 hours break in between. As a result, 0Z21 Wymondham to Keighley (KWVR), departed Wymondham at 14.43, and was routed via Ely, March, Peterborough, Spalding, Lincoln, Gainsborough, Doncaster (crew change), Knottlingley, Pontefract Monkhill, Crofton West Jct, Turners Lane Jct, Woodlesford, Engine Shed Jct, Whitehall Jct, Shipley, Keighley Station Jct, and then onto the KWVR. This was a very roundabout route, just to avoid approximately 8 miles of ECML, and there were not even any Branch Line Society members present. The journey was uneventful until just after Knottingley, when we were stopped by a red signal and the signaller calling on the GSMR. Chris, the driver, answered the call. The signaller informed Chris that IA48 the 18.45 Leeds to Kings Cross was stopped near South Elmsall, and that our loco convoy was the closest available manned loco to rescue the train if required. In June 2022, 1A48 was still formed of a Class 91 and Mk4 set, so 33012 would have been able to couple to it OK. Chris relayed the request to WCR control, who agreed to the rescue so long as the owner's rep (me) was happy with it. A plan was put in place to drop off 50026 and 33202 in some sidings, and for 33012 to run light engine to South Elmsall, couple to the rear of the train and push it to Doncaster, where it would be terminated and put away, then we would return to Knottingley, collect 50026 and 33202 and carry on to Keighley and the KWVR. Alas, before this rescue could take place, the signaller phoned back to say that the driver of 1A48 had been able to reset the Class 91 and we would not be required!!! There was sufficient slack in the schedule for us to make up the 30 minutes that had been lost while the 1A48 rescue was being set up, to allow us to arrive at Keighley Station Jct right time. From there a KWVR driver gave hand signals to the final WCR Driver Mick, to propel into Keighley KWVR Station where 33202 was started and hauled 50026 and 33012 to Howarth Loco Shed. KWVR Diesel Gala - Friday 10th to Sunday 12th June 2022The Diesel Gala did not begin until Friday 10th June. So on the morning of Wednesday 8th June, the KWVR shed staff conducted their own “Fitness to Run” (FTR) exams on 33012, 33202 and 50026, then the KWVR Diesel Group offered to wash 33012, an offer I gratefully accepted !!! 33012 had a couple of trips up and down the KWVR on Thursday 11th June shunting coaches ready for the Gala, which allowed for their sole driver with Class 33 traction knowledge, to carry out conversions the Class 33 type for other KWVR drivers. This was required, as alas no 71A Locomotive Group drivers with current Class 33 knowledge were available for the visit to the KWVR. 33012 was wired for sound by Allesandro Pulidori of Locoman Sounds. Allesandro has a formidable array of microphones, magnetic mounts, cables and an 8-channel digital recorder to capture an assortment of sounds of exhaust, engine, traction motors, brake cylinders, wheels, brake blocks, etc, which he mixes for use with scale model trains. All profits from Locoman Sounds are donated to the KWVR. KWVR is roughly 5 miles long, with 6 stations and a passing loop more or less in the middle of the line. The timetable was intensive with 2 x 5 coach trains running the full length of the line, and a 4 coach shuttle running from Keighley to Ingrow and back. The Diesel Gala itself was remarkably busy, and 33012 along with 33202 and 50026, all worked perfectly. It was also gratifying to hear compliments about 33012 and 33202, from some of the younger passengers who had never enjoyed Class 33 haulage before. We finished on Sunday evening back at Howarth Loco Shed, for mainline FTRs and topping up of the fuel tanks. Also, 71A Locomotive Group member Liam Trott arrived on Sunday, for the lengthy return journey back to Swanage on Monday. Southbound Mainline Move - Day No 1 - Monday 13th June 202233202 lead 50026 and 33012 from Howarth to Keighley. At the KWVR's Keighley Station, WCR driver Chris joined us on 33012 and he propelled the convoy onto Keighley Station Jct. The return to Wymondham was the same route as our northbound trip, except that we had the privilege of running on the ECML from Doncaster to Peterborough, instead of the previous circuitous route via Lincoln. 0Z22 Keighley to Wymondham departed Keighley at 09.09, then onward to Doncaster, then via the ECML direct to Peterborough, then via March and Ely, arriving at Wymondham at 14.36. At Wymondham, the MNR crew met us at the mainline connection and drove the convoy to Kimberley Sidings again. This time Liam and I stayed in Norwich along with the WCR crew. Southbound Mainline Move - Day No 2 - Tuesday 14th June 2022In the morning 33012 propelled 50026 from Kimberley back to the mainline connection at Wymondham, and back onto the mainline. The final route back to Swanage was an exceptionally long way round !!! 0Z33 Wymondham to Swanage departed Wymondham at 07.24, then went via March, Peterborough, Oakham, Leicester, Nuneaton, Washwood Heath, Tyseley, Oxford, Reading West (avoiding the main station at Reading), Basingstoke, Winchester, Southampton Central, and Wareham, finally arriving back at Swanage at 18.20 in the early evening. Friday 3rd June 2022Final stage of Cab Overhaul:Welcome to this special news update covering the final stage of the cab overhaul on 33012 (D6515). With the cab overhaul on 33012 now completed, it is only right that the 71A Locomotive Group highlights the magnificent support that the Group has received from Barry Stephens, the boss of Arlington Fleet Group Ltd, and all of his staff. Barry has been very generous in providing the Group the workshop space that allowed us to carry out the work on 33012 undercover and in the dry, something that is critical when we were removing the roofs off both of 33012's cabs. On top of this, we had access to overhead cranes, welding equipment, and other engineering equipment. This support that the Group received from Barry and all of his staff is gratefully appreciated by the committee of the 71A Locomotive Group. All the following photos are copyright Alan R. Hawkins.

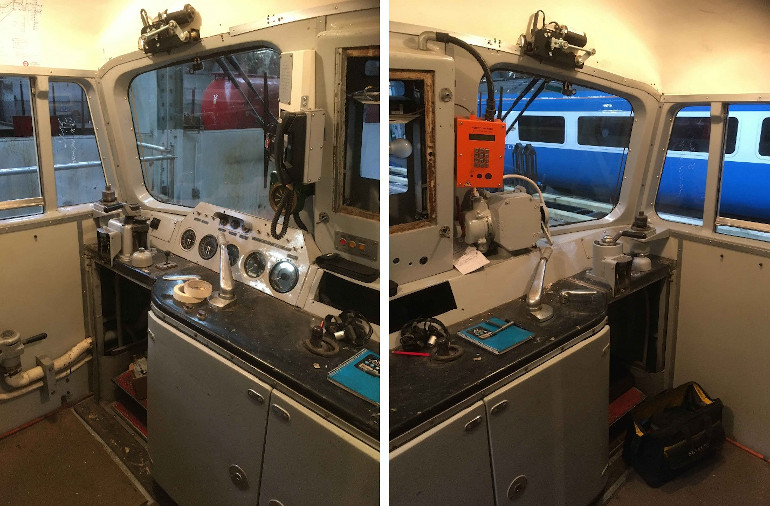

What a difference a year makes !!! The left-hand photo above shows 33012 during the cab strip downs on Saturday 6th March 2021. The right-hand photo above shows a completed 33012 on Sunday 3rd April 2022. The main work required to finish off the overhaul of both of 33012's cabs, has involved the fitting of all the final bits and pieces that were removed in early 2021, such as the various driver and secondman controls, the GSMR equipment, the final internal panelling, all the various bits of aluminium trim, all four cab seats and armrests, both cab roof cupboards, etc, etc. In the case of the internal panelling in both cabs, the old painted fibreboard was susceptible to water damage over time, which in turn affected its structure and colour, so this was replaced with brand new glass reinforced plastic (GRP) panels which doesn't absorb water, so will therefore last a lot longer. All four of the driver's and secondman's seats, along with their associated armrests, where re-upholstered with nearly new seat covering material that was carefully recovered (with the permission of Arlington Fleet Services) from Class 317 EMUs being scrapped at Eastleigh Works. Another cab item that needed some work to bring back to serviceable condition, was the cab floor panels in both cabs. These cab floor panels needed to be either fully refreshed, or in the case of a few of the panels, completely replaced. With all of the cab floor panels (old or new) this worked involved replacing both the lino floor covering and the special T shaped aluminium edging strips, with brand new material. The following series of photos show examples of the work carried out in the final few months of the cab overhaul work.

Two views of 33012's No 2 Cab, both taken on Sunday 6th February 2022, showing the various refitted items such as the driver and secondman controls, the GSMR equipment, the final internal panelling, and some of the various parts of the aluminium cab trim (but not all of it at this stage in the rebuild).

All of the remaining various parts of the aluminium cab trim after cleaning on Sunday 6th February 2022, prior to the final polishing and then refitting into both of 33012's cabs.

71A Locomotive Group Lead Technical Officer James Cox is seen adjusting the fit of the driver's windscreen on 33012's No 2 Cab on Sunday 13th February 2022.

One of the cab floor panels with its new lino and original lifting handle already refitted, and now having the brand new special T shaped aluminium edging strips cut, shaped and fitted as required, as seen on Sunday 13th March 2022. The photo on the right shows a close-up of one of the corners, showing how the brand new aluminium edging strips were cut and shaped.

And the finished product. One of the cab floor panels with everything attached, and so ready for refitting to one of 33012's cabs on Sunday 13th March 2022.

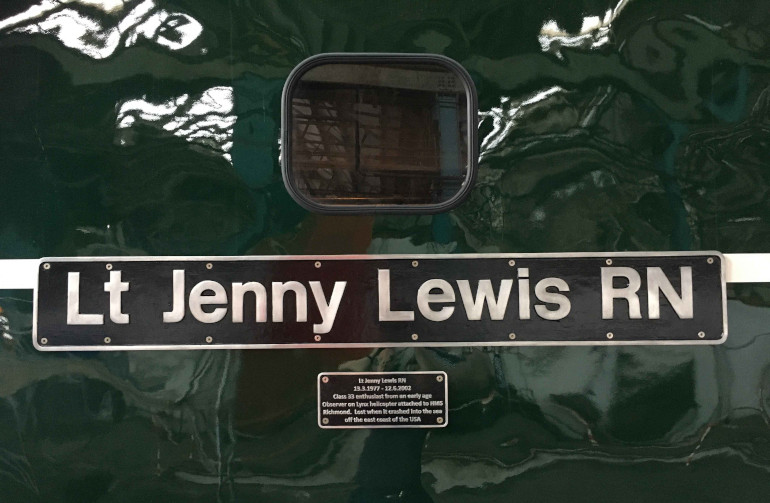

71A Locomotive Group volunteers Tim James (in the photo on the left and holding the drill in the photo on the right) and Richard Kirwin (waiting to help Tim in the photo on the right) are seen refitting the 'Lt Jenny Lewis RN' nameplates to the 'B' side of 33012 on Sunday 3rd April 2022. Several of the fixing holes for the nameplates needed a bit of fettling after the bodyside strip moved very slightly during the repaint, so the nameplate needed to be realigned with it.

The photo above shows the refitted 'Lt Jenny Lewis RN' nameplate on the 'A' side of 33012, during the final working party on Saturday 9th April 2022. All the different plates refitted to 33012 have been cleaned, repainted and polished, so that they match the excellent finish of the rest of 33012.

Mission Complete. 33012 sits outside the main workshop building at Eastleigh Works, during the final working party on Saturday 9th April 2022, looking absolutely immaculate in her new paintwork.

Less than a week later and 33012 is seen at the exit of Eastleigh Work on Thursday 14th April 2022, about to depart the Works for the first time in just over 15 months, on route back to the Swanage with 50026 'Indomitable' in tow (and from where this photo was taken).

33012 and 50026 sit at Wareham on Thursday 14th April 2022, shortly before passing Worgret Junction and crossing onto the Swanage branch, and then arriving back on the Swanage Railway proper. May 2022 News UpdateSevern Valley Railway Diesel Gala Report - James Cox:The committee of the 71A Locomotive Group received an approach from the Severn Valley Railway (SVR) on 23rd April 2022, saying that the planned visit of a Deltic locomotive to their Spring Diesel Gala running from Thursday 19th through to Sunday 22nd May 2022, had fallen through and they were looking for a replacement. The SVR immediately thought of 33012, because there was a mainline transit move planned after the Swanage Railway Diesel Gala, routed via SVR Kidderminster to drop off two Peak locomotives. After some negotiation about hire fees, a plan was developed. 33012 was added to the West Coast Railway (WCR) operated convoy of locomotives running from Swanage to Kidderminster on Tuesday 10th May 2022. The plan was for 33012 to lead and be in multiple with 31128, hauling 37703, D4, and D182. The route was as follows:- Swanage (departing 06.10), Wareham (departing 06.56), Southampton Central, Winchester, Basingstoke, Reading West (avoiding the main station at Reading), Oxford, Wolvercote Jct, Moreton-in-Marsh, Evesham, Worcester Shrub Hill and Kidderminster (arriving at 13.19). 71A Locomotive Group member and Swanage Railway driver Dave Gravell and I accompanied 33012 on this move, and there were no problems enroute. On arrival at Kidderminster (the mainline station), the WCR crew propelled the convoy into the SVR transfer siding. From there 33012 was uncoupled from 31128 and then stabled in SVR's own Kidderminster Station. 31128 and 37703 were uncoupled from the two Peaks and made their way back out onto the mainline for the 31128 to take the 37703 to Barrow Hill. 33012 then shunted the Peaks onto Kidderminster Diesel Depot. As it was over a week to go before the start of the Diesel Gala, Dave and I made our way home to Dorset by train. At the SVR Spring Diesel Gala itself, 71A Locomotive Group members Ian McDavid, Kev Hare, Alan Hawkins, Joe Loughlin, and myself represented the Group. Ian was the Group's representative Class 33 qualified driver who worked with SVR diesel drivers. 33012 hauled trains on all four days of the SVR Spring Diesel Gala. On Thursday 19th May, she worked one round trip from Kidderminster to Bridgnorth and return, then a Kidderminster to Bewdley and return shuttle. On Friday 20th May, she hauled two round trips from Kidderminster to Bridgnorth and back. Unfortunately, while hauling the 18.50 Bridgnorth to Kidderminster service, 33012 suddenly suffered a total loss of power while approaching Bewdley. This was caused by a broken pipe to the vacuum control circuit governor. Luckily I was able to carry out a temporary repair to isolate the vacuum control circuit governor, and plug the small-bore vacuum pipe, but the SVR Operations team decided to carry out a full recovery exercise with detonators and other implements of distraction !!! So 33012 had the ignominy of being piloted by 50007 for ¼ mile into Bewdley Station. Then followed some lengthy shunt moves to get 50007 off the front of 33012, and replace it with D1062. The train finally left Bewdley at a rapid pace with both D1062 and 33012 at full power. We arrived back at Kidderminster considerably late. A number of passengers had been trying to outdo each other with suggestions as to what had caused 33012 to lose power. Amazingly these ideas even included traction motor flashover or main generator flashover. I have encountered both of those faults on other locos and can assure everyone that a flashover, no matter how small, is always accompanied by a smell of electrical burning. Nobody could recall any such unusual smells coming from 33012 during this incident. We were met at Kidderminster by Steve Wainwright, the SVR Head of Operations and a founder member of the Diesel Traction Group (DTG). Steve very kindly made available to me the Kidderminster Diesel Shed, and all the DTG's tools, parts and equipment. This meant that I was able to make a proper long term temporary repair with a piece of flexible hose and some hose clips. The remainder of the SVR Spring Diesel Gala was uneventful, and 33012 managed to gain the class a few new followers, with some passengers at the Diesel Gala having never been hauled by a Class 33 before. On Monday 23rd May, 33012 hauled D4 from Kidderminster to the Midland Railway Centre at Butterley. For some unknown reason, Peaks are now banned from the direct route from Kidderminster to Birmingham via Old Hill for gauging reasons. So, the route was first south to Worcester Shrub Hill, run round there and then north towards Birmingham via Bromsgrove. With only a single Class 44 in tow, 33012 was not at all taxed by the Lickey Incline. We then went via Longbridge, Landor St Jct, Water Orton, Burton-on-Trent, Stenson Jct, Sheet Stores Jct, Toton Centre and onto Codnor Park Jct for the Midland Railway Centre at Butterley, where D4 was stabled. Shortly after departure from Codnor Park Jct to head light engine to Swanage, the GSMR radio signal dropped out a few times then dropped out completely. There were two WCR drivers on 33012 at the time, one of whom is a Traction Inspector. The inspector phoned the area signalling centre via his mobile phone and explained about the GSMR signal, the signaller told him that they had a major fault with the GMSR service in the East Midlands and that we should carry on. The GSMR signal did return briefly around the area of North Stafford Jct, but then the GMSR radio display indicated Fault F3. I phoned Jim, the Network Rail Southern Region GSMR Field Engineer who had fitted the upgraded v4 radio to 33012 in Eastleigh Works and reported the fault. Jim confirmed it was bad news, as a number of radios from the v4 upgrade had the same problem, likely to be the SIM card inside the radio coming loose. Our only option was to clear the mainline and obtain a replacement radio. We were only a few miles from our friends at Nemesis Rail at Burton-on-Trent, I phoned Richard, one of the directors of Nemesis, who confirmed that they did have spare upgraded v4 GMSR radios in stock for one of their own locos, but that we could use it in 33012. The WCR drivers made arrangements with signallers for 33012 to run to Coleshill Parkway station, and then reverse direction to go to Nemesis, with the Inspector phoning in every few minutes to maintain contact. 33012 got to Nemesis Rail OK. When stabled, Richard phoned the Network Rail Midlands Region Field Engineer Phil, to ask him to attend to 33012 with his dedicated GMSR laptop to set up the radio to the loco. There was alas one big problem. Phil, Jim and all other area GMSR engineers were in hotels in London, on standby for the opening of the Elizabeth Line that week !!! The only option available was for someone (me) to go to WCR at Carnforth, to borrow their GSMR laptop and get it back to Nemesis. WCR agreed to take 33012 back to Swanage on the following day, as luckily both drivers were available. So I looked at train times and worked out that I would have to stay overnight in Carnforth, and get the first train I could back in the morning, with the WCR GMSR laptop. So I booked a room in the Station Hotel at Carnforth, and a member of Nemesis staff gave me a lift to Burton-on-Trent station and I made my way to Carnforth. On arrival at Carnforth station, Gareth Williams (the WCR Diesel Fleet Manager) met me with the precious GSMR laptop. I got the first train southbound from Carnforth, and was back at Nemesis by mid-morning. I gave the laptop to Ollie, Nemesis' chief electrician, who had already swapped the defective GSMR radio out of 33012 and replaced it with a spare serviceable one. Ollie connected the interface cable and was able to set up the radio with 33012s specifications. A test call to Network Rail proved that the radio was working correctly. The two WCR drivers were on site by now, and we left Nemesis and joined the mainline, picking up the same path as the previous day. The route back to Swanage was Burton-on-Trent, Water Orton, St Andrews Jct, Dorridge, Oxford, and into Reading. At Reading there was a pathing stop and crew change in bay Platform 3. From the number of GWR drivers who came over to see 33012, wanting to drive it rather than GWR's IETs, I don't think GWR could have claimed a driver shortage that day !!! The final part of the trip back to Swanage via Winchester and Southampton Central was uneventful. Saturday 21th May 2022Severn Valley Railway Diesel Gala:A couple of pictures taken during during the Severn Valley Railway's Spring Diesel Gala. All the following photos are copyright Alan R. Hawkins.

33012 is seen at Arley with the 14.15 Bridgnorth to Kidderminster on Thursday 19th May 2022, during the Severn Valley Railway's Spring Diesel Gala. This was 33012's first trip as a visiting locomotive to another preserved railway, since leaving Eastleigh Works just over a month before.

33012 is seen passing over the level crossing at Northwood Halt with the 15.10 Kidderminster to Bridgnorth on Saturday 21st May 2022, during the Severn Valley Railway's Spring Diesel Gala. Friday 20th May 2022Minor Failure at the Severn Valley Railway:D6515 (33012) was working the 18.50 Bridgnorth to Kidderminster, when about quarter of a mile before Bewdley, it suffered a failure of the vacuum train pipe circuit governor pipe, that cracked under the secondman's desk in No 1 Cab. A temporary fix was carried out straight away by James Cox. But by this stage the SVR had started organising rescue locos. So 50007 off the 19.40 Kidderminster to Bridgnorth, assisted 33012 into Bewdley. 50007 was then put back onto its own train. Then D1062 (which arrived light engine from Kidderminster) worked in tandem with 33012 on the 18.50 Bridgnorth to Kidderminster, all the way back to Kidderminster. 33012 made a good effort of drowning out the noise of the Western. May 2022Summer Galas:After a successful Swnage Railway Diesel Gala, 33012 pulled 0Z33, a convoy of locos to Kidderminster on the Severn Valley Railway. These were 31128, 37703, 44004, and 46045. 33012 will be in action at the Spring Diesel Gala at the SVR, on 19th to 22nd May. After the Severn Valley Railway gala, 33012 will head back to Swanage. However, it will soon be off again to participate in the Keighley and Worth Valley Diesel Gala being held 10th to 12th June. It will also take 50026, which is still at Swanage, to Yorkshire. Photos below are copyright Richard Kirwin.

April 2022Return to Swanage:On the 14th April 33012 pulled 50026 from Eastleigh Works back to Swanage. Both locos will be working at the Swanage diesel Gala running from 5th May to 8th May. The photo below is copyright Jon Biglowe.

Out of the Works:33012 emerged from Eastleigh Works on Saturday 9th April. Video and photos below are copyright Richard Kirwin.

February 2022The 71A AGM was held in Eastleigh Works on Saturday 19th February. Those present were told of the progress on the cab overhaul of 33012. The work is mostly complete, and after testing, it is hoped the loco will be returned to Swanage in the near future.

Largely complete 33012 back in the main works for completion of cab and body overhaul. January 2022Welcome to this special news update covering the next stage of the cab overhaul on 33012 (D6515). This issue is out a couple of weeks later than planned due to work and family commitments combining with Christmas and New Year, along with all the work related to 33012's cab overhaul (both on and off the loco). Alas there are only so many hours in a day. This is one of the reasons why the committee URGENTLY needs to fill the presently vacant role of the group's Secretary. Talking of meetings and AGM's, the Group's 2022 AGM will be taking place on Saturday 19th February 2022 in one of the meeting rooms in Eastleigh Works. Due to all the COVID restrictions in place during early 2021, it wasn't possible to stage a 2021 AGM, so this is the first AGM in two years, since the 2020 AGM that took place on Saturday 15th February 2020 in Eastleigh Works. All the following photos are copyright Alan R. Hawkins.

Before and After - The left-hand photo above shows 33012 inside the Paint Prep Area inside Eastleigh Works on Saturday 6th November 2021, being prepared for the next coat of paint after the yellow warning panel had been applied and then masked-up. The right-hand photo above shows 33012 inside one of the Paintshop Spray Booths on Saturday 13th November 2021. What a massive difference a week can make !!! Cab Numbers One and Two:With the repaint of 33012 complete, bar a small amount of painting of the handrail ends, etc, and the odd bit of touching up here and there, all of the remaining work on 33012 is now centred on refitting all of the bits and pieces back into both of 33012's cabs. The fitting of the supporting hardwood structure that all the internal fibreglass window surrounds, internal roof lining etc. are screwed to is now almost complete apart from an odd bit of wood here and there. Now the job of refitting all the many internal items such as the fibreglass window surrounds, internal roof lining, cab partitions, etc. has started in earnest. At the present moment in time 33012's No 2 Cab is just slightly ahead of 33012's No 1 Cab. Another important job that has been carried out, is the complete rewiring of all the upper electrical wiring in both of 33012's cabs, which has been carried out by the 71A Locomotive Group Lead Technical Officer and electrical guru James Cox. While the bulk of the electrical wiring in both of 33012's cabs was replaced during the mainline overhaul between 2009 and 2011, the electrical wiring hidden in the cab roofs and cab partitions wasn't replaced, as it could not be easily reached. Now with both cabs stripped down, this was the ideal time to replace the remaining original electrical wiring in both of 33012's cabs. The following series of photos show examples of the work carried out in the last two and a half months.

Cab Droplight Windows - In the left-hand photo above, the refitted driver's cab droplight window, and in the right-hand photo above, the refitted secondman's cab droplight window (both in 33012's No 1 Cab), are shown on Saturday 1st January 2022 (New Year's Day). This was all recently instilled by 71A Locomotive Group volunteer Kevin Hare during December 2021, along with the driver's and secondman's droplight windows in 33012's No 2 Cab.

Driver's Instrument Consoles - In the left-hand photo above, 71A Locomotive Group volunteer Dave Gravell is seen busy putting the finishing touches to the repainting of one of the driver's instrument consoles on Sunday 5th September 2021. While in the right-hand photo above, one of the driver's instrument consoles is seen on Saturday 11th December 2021, after refitting to 33012's No 2 Cab.

Brand New Electric Windscreen Wiper Motors Part 1 - In the left-hand photo above, 71A Locomotive Group Lead Technical Officer James Cox is seen installing one of the mounting plates for the brand new electric windscreen wiper motors to 33012's No 2 Cab on Sunday 5th September 2021. While in the right-hand photo above, shows one of these mounting plates with the new wiper arm pivot and wiper arm driveshaft fitted to 33012's No 1 Cab on Sunday 9th January 2022 (the first anniversary of the start of 33012's cab overhaul in January 2021). This is a good example of the improvements that are being made to 33012.

Brand New Electric Windscreen Wiper Motors Part 2 - In the photo above, one of the recently fitted brand new electric windscreen wiper motors assemblies is seen inside 33012's No 2 Cab on Sunday 9th January 2022 (the first anniversary of the start of 33012's cab overhaul in January 2021).

The photo above shows the headcode blinds assembly, its fibreglass surround, and the change end switch refitted to 33012's No 1 Cab on Saturday 1st January 2022 (New Year's Day).

The photo above shows some of the internal items such as the fibreglass driver's windscreen surround, internal roof lining and driver's cab partition, refitted to 33012's No 2 Cab on Saturday 1st January 2022. Funding for the Cab Overhaul Work - Donations URGENTLY Still NeededFirstly, thank you to everyone who has already made a donation to the Group's appeal for funding to cover the cab overhaul work. Your generosity is greatly appreciated. The 71A Locomotive Group committee calculates that we require £12,400 to cover all the final costs. If we can raise this money by donations from the Group's shareholders and support group members, then we will be able to fully cover the costs of the cab overhaul, and we won't have to borrow any money. For instance, if every single one of the 71A Locomotive Group's shareholder and support group member where to send in £40, which only equates to the cost of 10 pints of beer (or 20 pints if you happen to drink in Wetherspoons !!!), then the Group would raise £3,400 straight away. If we were to receive £146 from everyone, then the final costs of the cab overhaul would be totally covered !!! That said, we know that not everyone can afford to make such a donation, but we are at that point in time that every pound counts, so even a £5 or £10 donation will make a difference. So any further donations, however large or small, will be most gratefully received by the Group. Full details of how you can help with this appeal for funds can be found on the Donate page. October 2021Welcome to this special news update covering the next stage of the cab overhaul on 33012 (D6515). By the time you read this, 33012 will be in the paint prep area in Eastleigh Works, being readied for her trip into the paint shop. This issue was delayed a week or so, in case 33012 made it into the paint shop itself, but the paint prep has suffered a slight delay, due to the need to swap the No 1 cab driver's doors with one of the Group's spare ones, due to the present one on 33012 starting to delaminate. The cab door that was removed can itself be repaired in slower time, and then placed in the spares pool, so all is not lost. All the information in this issue is correct to Saturday 30th October 2021. So with the cab overhaul starting to enter its final phase, the committee of the 71A Locomotive Group has recently reviewed the Group's fundraising activities and work out how much extra effort is required. While the repainting costs have been covered thanks to one very generous 71A Locomotive Group shareholder, there are still a large number of bills to be paid, which means we need one final large push to cover all the final bills, etc, if possible. The committee calculates that we require £13,300 to cover all the final costs. All the following photos are copyright Alan R. Hawkins.

33012 inside Eastleigh Works on Saturday 9th October 2021, after the fitting of items such as the aluminium beading and electric windscreen wiper mounts, along with some final filling and sanding. Cab Numbers One and Two:With all the work to refit the fibreglass cab roofs now complete, the work has now turned to refitting the cab interiors. The first jobs being done are the fitting of the mounting brackets for the brand new electric windscreen wipers, and the fitting of the supporting hardwood structure that all the internal fibreglass window surrounds are screwed to. All the old hardwood structure was beyond repair, after being inside 33012's cabs since BR days. The old air powered windscreen wipers were also replaced, as they are now an obsolete system and spares are no longer available.

The two photos above show the fitting of the supporting hardwood structure that all the internal fibreglass window surrounds are screwed to, inside 33012's No 1 Cab on Saturday 16th October. Bodywork Overall:Prior to 33012 going into the paint prep area, both buffer beams were fully repainted by 71A Locomotive Group volunteer Kevin Hare. This part of the locomotive is too complicated for spray painting, so brush painting is more cost effective, plus by doing it ourselves, it saves the Group a bit of money.

A close-up of the repainted buffer beam for No 1 Cab on Saturday 9th October 2021. Cab Partitions:Work on all four of the cab partitions has now been finished, with the last job being the pop riveting of the four aluminium skins into place. Each partition needed 123 pop rivets, so that was nearly 500 pop rivets in total, which was made a lot easier by borrowing an electric pop rivet gun from one of the guys in the wheel shop at Eastleigh Works. Work on the cab partitions is therefore now fully complete, apart from the bolting the partitions into both of 33012's cabs, and a final coat of paint when the cabs are complete. Cab Roof Related Items:Another item that is now complete, is the repairs to the items that are mounted onto the cab roofs, such as the four cab roof vents. Two of these cab roof vents had some serious deterioration of the aluminium tubes that hold the internal closure mechanism inside the cabs, to the point the aluminium was oxidising and crumbling. This required the crumbling aluminium tubing being cut away and new aluminium tubing pop riveting in its place, with an aluminium transition piece between the old and new tubing. Also, one of the closure mechanisms needed dismantling and rebuilding with parts from a spare mechanism.

A close-up of the re-cutting of the handle thread on one of the internal closure mechanisms on Saturday 4th September 2021, ready for re-fitting into one of 33012's rebuilt cab roof vents.

A view of two of the cab roof vents, the one on the left before repair (with part of the crumbling oxidised aluminium visible), and the one on the right after being repaired. As seen on Sunday 5th September 2021.

A view of the No 1 end of 33012's roof, with the repainted radiator fan unit on the left of the photo, and the two cab roof vents refitted to No 1 Cab on the right. As seen on Saturday 18th September 2021.

33012 inside Eastleigh Works on Sunday 19th September 2021. August 2021

Updates for August on the cab overhaul work on 33012 at Eastleigh Works.

We have reach a milestone in the cab overhaul of 33012,

where we have now stopped cutting out rusty and corroded metalwork

(apart from a few minor patches here and there),

and we have now started to put items back onto 33012.

The biggest of these items is the test fitting of both cab roofs,

which still require a lot of fettling to both the refurbished roofs and all the new supporting metalwork,

before we can go for final fitting, but it really is great to have 33012 looking like a Class 33 again.

All the following photos are copyright Alan R. Hawkins.

33012 inside Eastleigh Works on Saturday 31st July 2021, during the first test fitting of the refurbished No 1 Cab roof. At this stage the roof isn't bolted down, it's just resting on the new supporting metalwork. Cab Numbers One and Two:Following on from having all the new metal sections manufactured to the original BRCW drawings, so that 33012 is being rebuilt to the original spec as far as possible, we have continued this policy with some of the most recent work. James Cox (the Group's Lead Technical Officer) has been hard at work refitting the original aluminium quarter light window frames to the new cab structure on both sides of both cabs. This is a really fiddly and difficult job, which needs a great deal of skill and effort to get right, so it is really great to see this original feature retained on 33012.

The top two photos above show the trial fitting of the glass to the Driver's side aluminium quarter light window frame, in 33012's No 2 Cab on Sunday 8th August 2021. The bottom two photos show the Secondman's side aluminium quarter light window frame, after refitting to 33012's No 1 Cab on Sunday 15th August 2021. Cab Partitions:All four of the cab partitions have now had all of their replacement supporting structure and steel skin welded into place, and the aluminium skins have had new aluminium sheet welded to their lower edges. The cab partitions just need the conduit for the cab heaters wiring welded into place at the bottom edge, the missing holes drilled into the supporting structure and the aluminium skins, and then the aluminium skin pop riveted into place. Each partition has 123 pop rivets, so that is nearly 500 in total, which is going to take a bit of time to fit !!! Work on the cab partitions is therefore now about 90% complete. Fibreglass Cab Roofs:The refurbishment of both cab roofs is now complete, with only the final fettling to both the refurbished roofs and all the new supporting metalwork, before we can go for final fitting. Work on the fibreglass cab roofs is therefore now about 90% complete.

33012's No 2 Cab roof sitting on the ground at Eastleigh Works on Sunday 1st August 2021, ready for test fitting onto 33012's rebuilt No 2 Cab structure. Cab Roof Related Items:Work has now started on all the items that are mounted onto the cab roofs, such as the four cab roof vents. These cab roof vents need all the old paint stripping off them, a full clean of all the opening and closing mechanism, the metalwork straightening, and a repaint with special metals primer. Then they are ready for refitting to the cab roofs.

The cab roof vent on the left is prior to stripping and cleaning. The cab roof vent in the middle has been fully striped and cleaned. The cab roof vent on the right has been painted with special metals primer. As seen on Sunday 15th August 2021. Cantrail Grilles and Aluminium Retaining Strip:While the work on the cantrail grilles, the new aluminium retaining strips and new aluminium beading is now 100% complete, below is a photo that wasn't available previously, due to just forgetting to take this particular photo before the last issue of "Spitfire" went out, due to all the other work that was going on at the time !!! The amount of riveting, bolting and filling required to complete this job was phenomenal.

A close-up of the refitted cantrail grilles, along with the new aluminium retaining strips and new aluminium beading on the 'B' side bodyside on Saturday 10th July 2021. This photo shows just a fraction of the work done to complete this part of the overhaul on 33012, and the same was done on the 'A' side bodyside. Bodywork Overall:The whole of the locomotive has had more imperfections filled with body filler, which need rubbing down and smoothed over. Also, work has started on refitting all the detailing items, such as the aluminium beading (including the fitting of brand new aluminium sections), and the re-drilling of the fittings for the cab front handrails, etc. This work is probably one of the worst jobs on 33012, as all of this work is very labour intensive and time consuming, but will never be noticed by anyone looking at 33012, as people will only be interesting in the glossy paint finish, not realising that all this prep work is critical to 33012's final gleaming finish.

A close-up of the refitted aluminium beading on the Secondman's side and front corner of the No 1 Cab on Sunday 15th August 2021. Bodysides:The work on the engine room doorways, and on the engine room doors themselves is now completed. The structural work on the bodysides is therefore now about 95% complete, with just the odd small pieces of patching to be dealt with.

The photo on the left shows the 'B' side engine room door after all the corrosion had been cut out. The photo in the middle shows the same with the 'A' side engine room door. The photo on the right shows the 'B' side engine room door after all the repairs, welding and repainting have been completed. June 2021

Updates for June on the cab overhaul work on 33012 at Eastleigh Works.

All the following photos are copyright Alan R. Hawkins.

Number One Cab:After the "little" job of completely stripping the cab, the other "little" job of cutting out all of the rusted and heavily corroded steel bodywork and supporting structures has been completed. At the front of the cab, everything north of the central handrail has been replaced with new metalwork, and with both cab sides, about 60% to 70% of the whole sides has been replaced with new metalwork. Also with Cab No 1, the cab door sills in both doorways and under both cab sides were heavily corroded as well, so these needed cutting out and completely replacing with new metalwork as well. A small amount of the cab floor structure was replaced with new metalwork as well. The welding of all of the replacement new metalwork is about 90% complete. Once this is completed, the cab roof can be refitted once it is ready. All the new metal sections were manufactured to the original BRCW drawings, and were cut to fit and welded in place by either Arlington Fleet Services staff or 71A Locomotive Group volunteers. So 33012 / D6515 is being rebuilt to the original spec as far as possible.

An external view of No 1 Cab of 33012 on Saturday 26th June 2021. All the bodywork in green primer or covered with filler is brand new metalwork.

The rebuilt No 1 Cab of 33012 on Saturday 26th June 2021 (before the window corners have been rounded and shaped).

Most of the metal painted black is brand new metalwork. Cab Number Two:The work on Cab No 2 is not as advanced as Cab No 1, but the level of work being done is broadly the same, minus the cab door sills in both doorways and under both cab sides, which didn't need replacing. Also, only one piece of floor structure needed replacing. The welding of all of the replacement new metalwork is about 70% complete. Again, once this is completed, the cab roof can be refitted once it is ready.

The lower part of the Secondman's side of 33012's No 2 Cab on Saturday 15th May 2021, after the outer skin has just been removed, so the heavily corroded areas behind could be worked on.

The same area of the Secondman's side of 33012's No 2 Cab on Sunday 6th June 2021, after the corroded metalwork shown in the photos above had all been cut out, and new metalwork had been welded in its place. By the end of June 2021, the new lower part of the outer skin had also been welded in place. Cab Partitions:All four of the cab partitions needed a lot of rusted and heavily corroded steel skin and supporting structures cutting out. Bearing in mind that these cab partitions form a structural part of the cab, as well as being the mounting points for the Driver's and Secondmen's seats, they are an important part of 33012. One partition needed only a small amount of remedial work, but the other three needed major surgery, with both the lower supporting structure and the side supporting structure that bolts to the cab sides, needing completely replacing. Again, all the new metal sections were manufactured by an engineering company to the original BRCW drawings, and were cut to fit and welded in place by 71A Locomotive Group volunteers. One cab partition is complete, two just need the replacement parts of steel skin welding into place, and the final one is having the new supporting structure fettled to fit and welded into place at this moment in time, before the replacement parts of steel skin are welded into place. The only other parts needing to be repaired, are the aluminium covering skin that face the cab doors, which all need the lower corroded sections cut-out and new aluminium welded into place. Then these repaired aluminium skins will need riveting to their original cab partitions. Work on the cab partitions is about 70% to 80% complete.

The Secondman's side cab partition from 33012's No 2 Cab on Sunday 6th June 2021, showing the new supporting structure that has just been welded into place, and then the welds smoothed down with an angle grinder flap disc. These partitions need a lot of work. Fibreglass Cab Roofs:This was one area on 33012, that the 71A Locomotive Group has had to contract out to a specialist repair contractor, and this contractor (Danny Armon) has been very busy recently. Both cab roofs have been fully cleaned, the corroded horn mounted plates removed, all the damaged and loose fibreglass sections removed, then all the damaged sections have been repaired, strengthened and built up with new glass fibre, and now the new sections are in the process of being trimmed to the correct size and profile on both roofs. These cab roofs look great and are vastly stronger now, which will mean they will last for many many more years before any further remedial work is required. Work on the fibreglass cab roofs is about 70% to 80% complete.

The two photos above show both of 33012's cab roofs on Saturday 26th June 2021, after the bulk of the repair work has been completed, but before the final trimming of the edges to the correct size and profile has taken place. May 2021Further updates on the work on 33012 at Eastleigh Works. All the following photos are copyright Alan R. Hawkins.

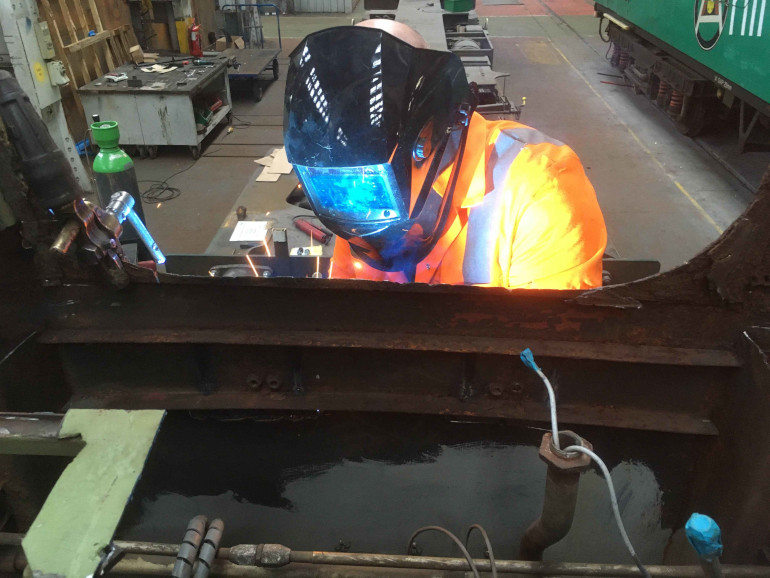

71A Loco Group Volunteer Kevin Hare busy welding 33012 on Saturday 3rd April

New structural support above one of 33012's cab doors for the No 1 cab - Saturday 10th April 2021

Making replacement patch plates for 33012's cab skin - Saturday 10th April 2021

Corrosion repairs to the Change End Switch Mountings - Sunday 18th April 2021

33012's No 2 Cab being rebuilt - Sunday 2nd May 2021 April 2021Work continues on 33012 at Eastleigh Works. All the following photos are copyright Alan R. Hawkins.

33012 with both cab roofs removed on Saturday 6th March 2021

The extensive corrosion that was found hiding within the right hand cab door step for No. 1 Cab,

An external view of the re-welding of No. 1 Cab, on Saturday 10th April 2021

The re-welding inside of No 1 Cab of 33012 on Saturday 10th April 2021 January 2021Work on 33012 has started at Eastleigh Works. All the following photos are copyright Alan R. Hawkins.

Inside Eastleigh Works - Saturday 23rd Jamuary 2021

Nameplates before removal - Sunday 24th January 2021

Nameplates after removal - Saturday 30th January 2021

Numbers being removed - Saturday 30th January 2021

Cantrail Grilles on 33012 with the Grille Covers Removed - Saturday 23rd January 2021

Corrosion above the Driver's side window in No 1 Cab - Saturday 30th January 2021

Corrosion on the inner part of the Driver's pillar in No 1 Cab - Saturday 30th January 2021

Corrosion underneath where the AWS Switch Base is mounted - Saturday 23rd January 2021

Driver's console ready to be removed from No 1 Cab - Saturday 23rd January 2021

Driver's side of No 1 Cab during stripping - Saturday 23rd January 2021

Driver's side of No 1 Cab during stripping - Saturday 30th January 2021

Example of the corrosion of some of the screws on 33012 - Saturday 30th January 2021 January 202133012 travelled light engine from Swanage to Eastleigh Works as 1Z33 on Monday 4th January. 33012 is at Eastleigh Works, to undergo corrosion repairs to the upper cab structures and fibreglass repairs to the cab roofs, on both of 33012's cabs. August 2020The Swanage Railway is now operating a two train service, one steam, the other diesel, between Swanage and Norden. 33012 and 33111 are sharing the diesel turns. July 2020On 8th July 33012 celebrated it's birthday, it was 60 years ago that D6515 entered service at Hither Green depot. Following the Covid-19 lockdown, 33012 and 33111 alternately worked the diesel only service between Swanage and Norden. March 2020The webite has now been resurected on the new domain name 71locogroup.co.uk. Initially it will appear much as the old site, but in time it will be completly revamped. On Friday 6th March, 33012 travelled light from Swanage to Southall WCRC. On Saturday 7th March, 33029 headed the BL railtour from Lancaster to Paddington. On Sunday 8th March, 33207 and 33012 hauled the BLS Devonian Crompton railtour from London Victoria to Coleford Junction in Devon, and back to London Waterloo. On Monday 9th March, 33012 travelled light engine back from Southall to Swanage. February 2020The 71A Locomotive Group held it's AGM in Eastleigh Works. Among the items discussed was the need for someone to take over the website. In addition, the domain name 71A.co.uk had been allowed to lapse, and was now in use by another company. Jon Biglowe volunteered for this role. |